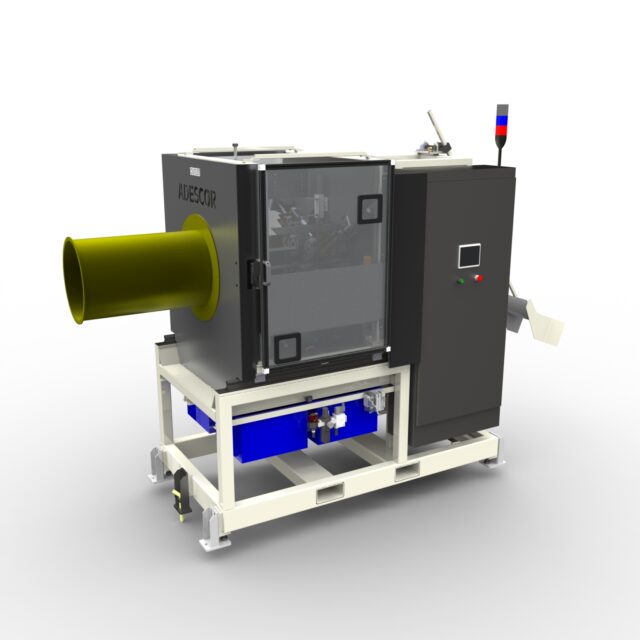

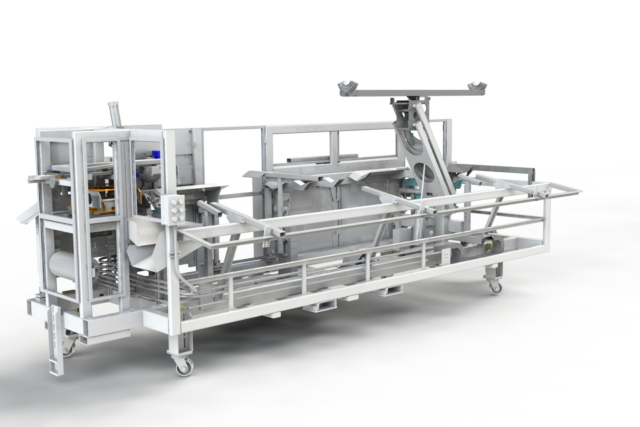

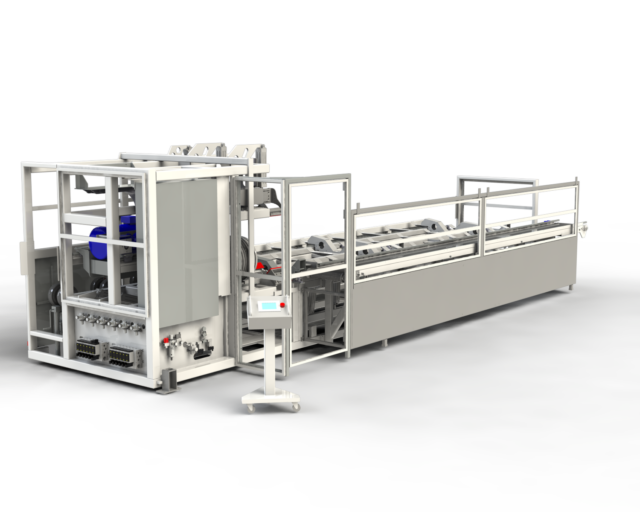

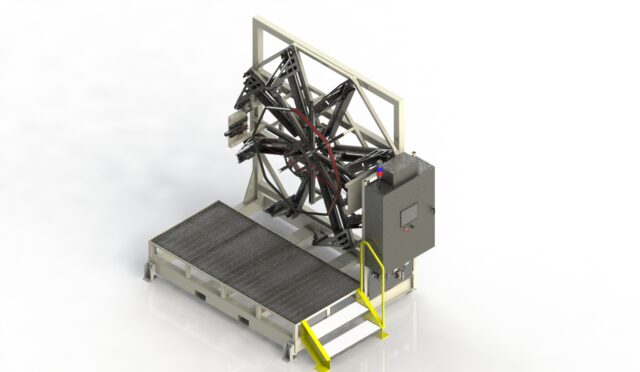

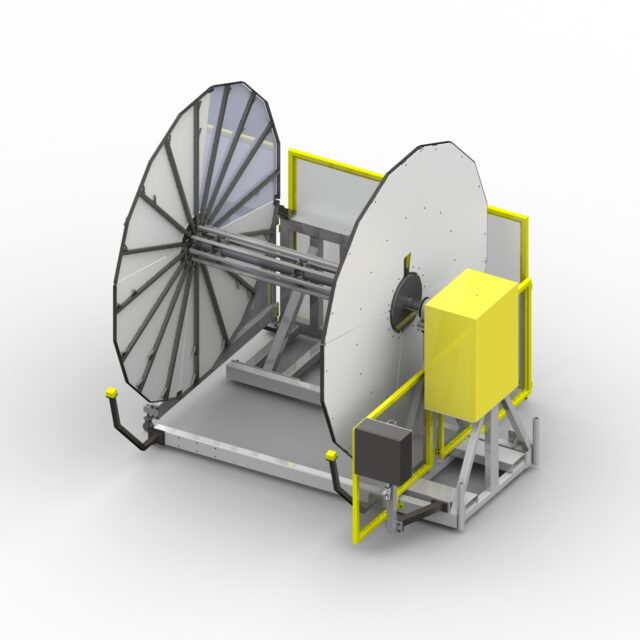

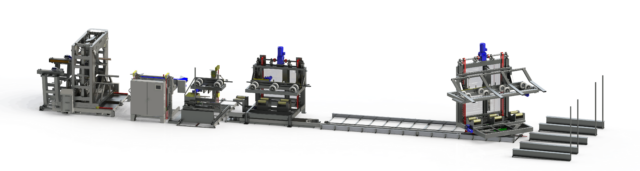

Core Products

Downstream Solution Experts

Adescor offers a full suite of downstream equipment for the corrugated and extruded pipe industry. We design, build, and support a comprehensive line of downstream equipment and as a system provider we ensure that all equipment is fully integrated.

Should our standard products not meet your production requirements, we can work with you to customize our equipment to suit your needs.

Custom Machinery

Contact Parmerit, our custom automation division for any custom machinery needs.