Pipe Coilers

Product Details

Adescor offers a range of mini and maxi-coilers for both corrugated and smooth wall pipe up to 375mm (15“) in diameter.

Maxi-Coilers feature variable speed drive systems that allow the operator to set the speed as required during operation. Maxi-coilers produce coils up to 3.2m (126“) which can exit to the front, rear, or side to suit various line configurations.

Adescor offers single and dual sided mini-coilers to coil pipe up to 150mm (6“) onto rolls up to 2.2m (87“) in diameter. Dual sided coilers have two coiling stations to allow for continued coiling of pipe while the manual string tying and unloading takes place at the second station. Controls are mounted between the reels on the

upstream side of the coiler and each reel is equipped with a foot switch for coiling.

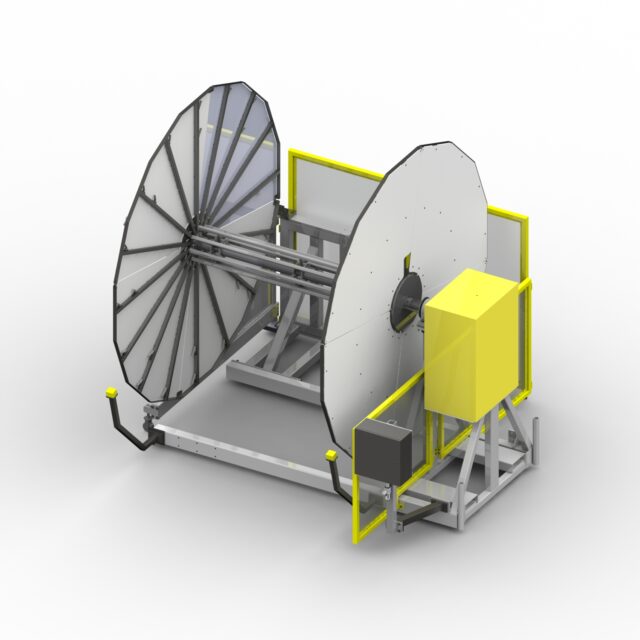

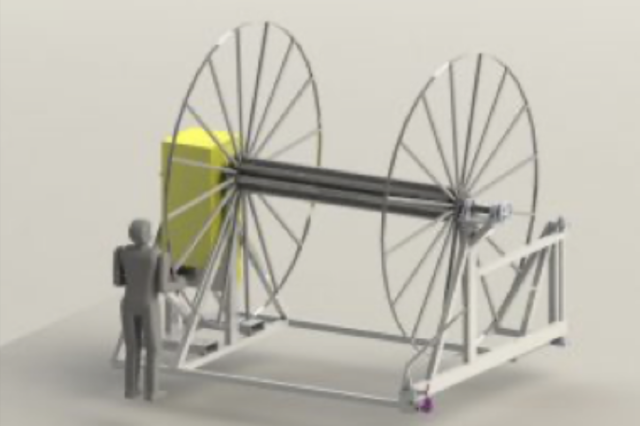

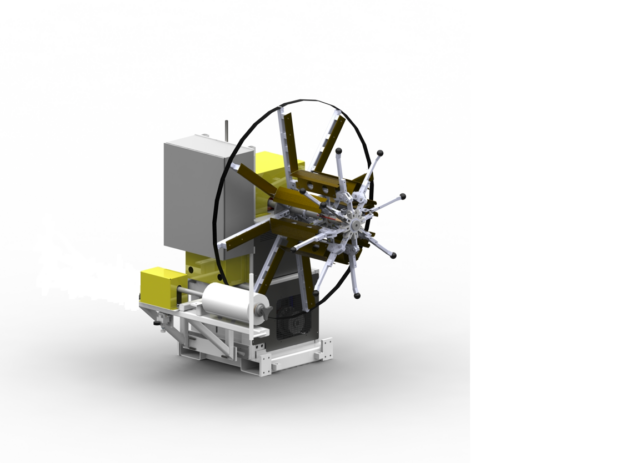

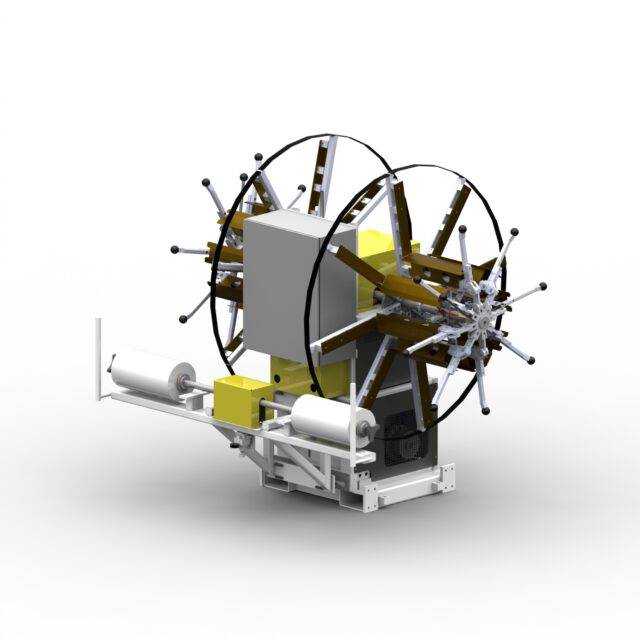

Maxi Coiler

Basic Maxi-Coiler

Front Exit Maxi-Coiler

Features

- 75 - 375mm (3 - 15”) pipe diameter

- Speeds up to 40m/min (130 ft/min)

- Variable speed drive system

- Pipe locking device for coil start

- Side safety guards

- String retention clips

- CSA certified electrical panels

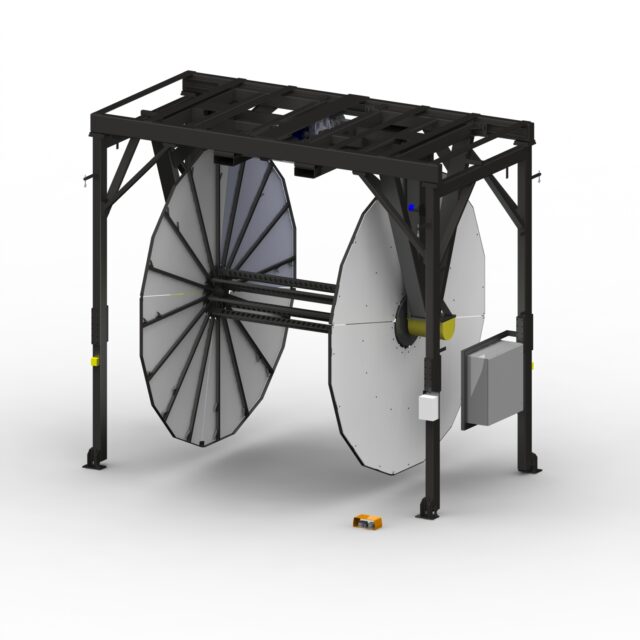

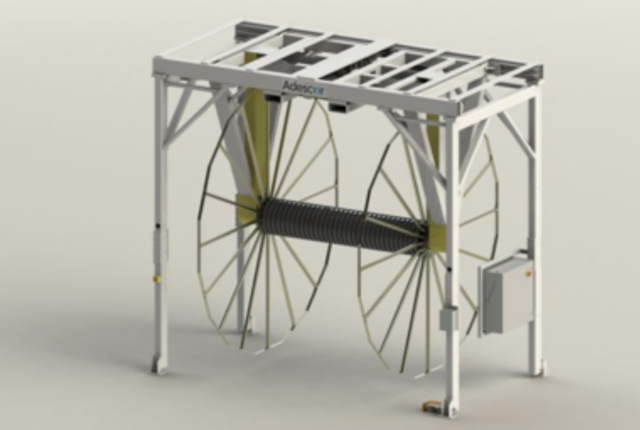

Mini Coilers

Single Head Mini Coiler

Dual Head Mini Coiler

Features

- 75 - 150mm (3 - 6”) pipe diameter

- Speeds up to 210m/min (700 ft/min)

- Variable speed drive system

- Pipe locking device for coil start

- Left, right or dual coiling

- Optional wrap feature

- CSA certified electrical panels

Specifications

| Name | Model | Pipe Diameter | Max Pipe Length (4" diameter) | Max Coiling Speed* | Inner Coil Diameter | Outer Coil Diameter | Coil Width |

|---|---|---|---|---|---|---|---|

| 415 Side Exit Maxi Coiler | 415-SEC01-X | 4" - 15" | 3600' | 130 ft/min | 15" | 126" | 87" - 94" |

| 415 Front Exit Maxi Coiler | 415-FEC01-X | 4" - 15" | 3600' | 130 ft/min | 15" | 126" | 87" - 94" |

| 36 Dual Head Mini Coiler | 415-DMC01-X | 3" - 6" | 250' | 700 ft/min | 20" | 72" | 20" - 24" |

| 36 Single Head Mini Coiler | 415-SMC01-X | 3" - 6" | 250' | 700 ft/min | 20" | 72" | 20" - 24" |

| 051 Pex Coiler | - | 0.5" - 1" | - | 200 ft/min | 21" | 34" | 1" - 10" |

Contact Us

"*" indicates required fields